See page 41 of SLC 500 Instruction Set for details on the OSR and note the different implementation on some of the PLCs. You need to use a one-shot to detect the rising edge of the IR sensor to latch B:3/0 and have it unlatch with the timer.DN. The problem you're having is that the sensor is staying on after the end of the timing cycle. (Also, note how shrinking the Windows window before taking the screengrab will give the readers a much more readable image in StackExchange's 640 pixel wide column format.)Īfter corrected timing diagram has been provided: _įigure 4.

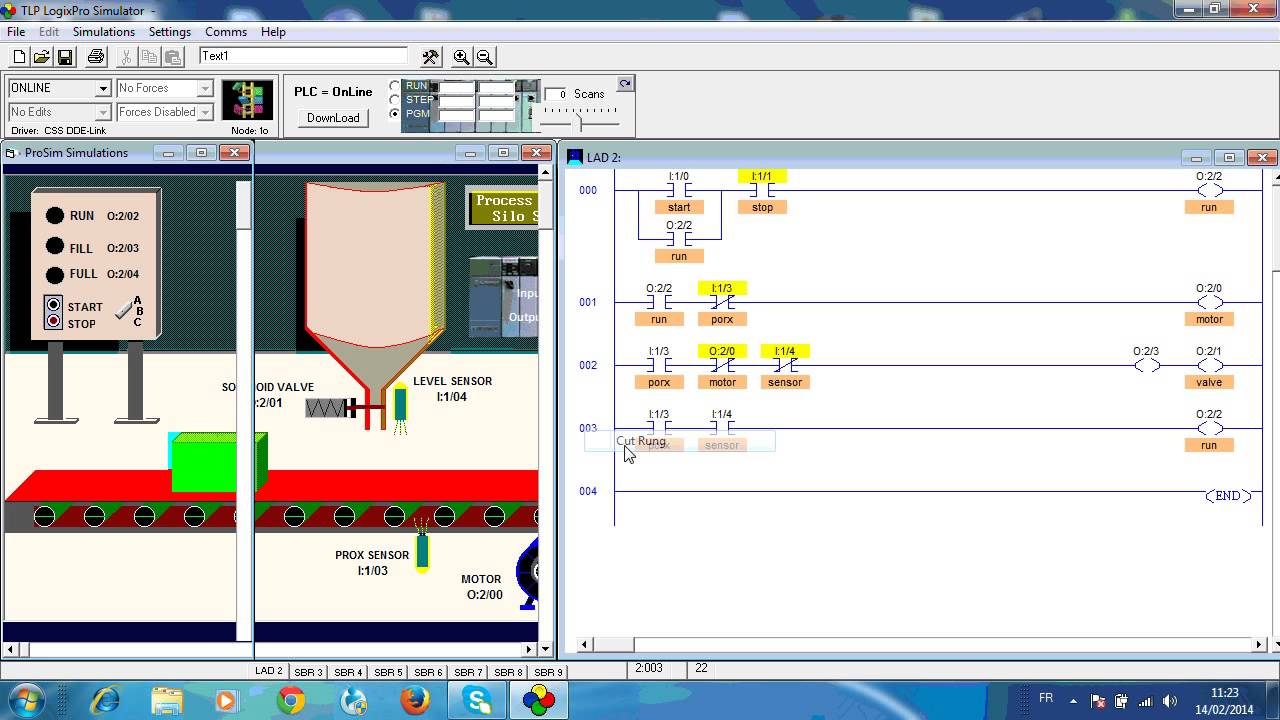

Thank you.ĮDIT: This is my final circuit. So is there a reason why the timer is always working, or does it depend on the used software? Moreover, is there a need for the Switch and IR Sensor inputs to be in the 2nd ladder, since the belt is enough to control the timer. Moreover, I am not sure how can I add a memory to indicate that the timer has already ended, and the belt should start moving again (OR DONE with the IR Sensor?) Also, when I simulate, the timer keeps resetting and restarting itself, although video tutorials online showed that all timers stopped after they reached their preset time. I am not sure of the correctness of the diagram, however. After the 5s and the reset of the timer, I wish to have the belt start moving again (Note that at this stage the IR Sensor is still off), and the cycle is repeated. During the first second, "Press" is also turned on. For the duration of 5s, "ValveD" and "ValveU" are both turned on. Afterwards, the IR Sensor is activated, turning off the belt, and initiating the timer. The process I have in mind is as follows:Īs the switch is closed, the belt is activated. I am doing a simple ladder diagram, and I came up with the following diagram:

This is my second day of learning PLC online.

0 kommentar(er)

0 kommentar(er)